charpy impact test on pipe|charpy impact test formula : exporter The charpy impact test of steel pipes has a wide range of applications. Aerospace Industry: Charpy impact tests can be used to assess the impact loads that aircraft structures and .

Perfume Poderosa inspirado no perfume Fantasy colônia de .

{plog:ftitle_list}

Acesse a academia Sou Mais - Betonex. Aulas de Musculação. Aberto Seg a Sex: 6:00-22:00, Sáb: 10:00-15:00. . Piraquara, Paraná . Escola Municipal Bernhard Julg (school), Sou Mais - Betonex is the right choice if you’re looking for a full-service gym. It offers fitness and group classes, with a team ready to help you achieve your goals .

Once the Charpy impact tester completes the test, the results are typically presented as the amount of energy absorbed during the fracture, measured in joules. These Charpy impact test results help manufacturers and engineers determine whether the material is suitable for its .Charpy impact testing is a method used to determine the toughness or impact resistance of materials, particularly metals. It measures the amount of energy absorbed by a material during fracture, providing valuable insight into its .The ISO 148-1 standard specifies the Charpy (U-notch and V-notch) impact test on metals for determination of the impact strength. The impact strength of a material is an important characteristic for applications in pipeline construction .The Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain-rate test that determines the amount of energy absorbed by a material during fracture. This .

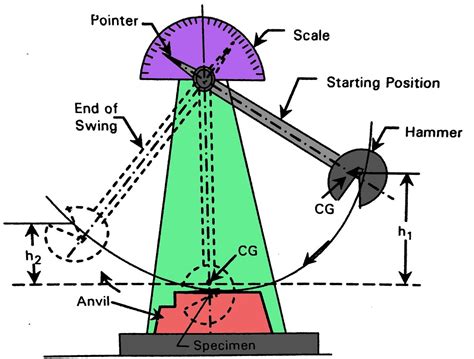

In materials science, the Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain rate test which determines the amount of energy absorbed by a material during fracture. Absorbed energy is a measure of the material's notch toughness. It is widely used in industry, since it is easy to prepare and conduct and results can be obtained quickly and cheaply. A disa.The charpy impact test of steel pipes has a wide range of applications. Aerospace Industry: Charpy impact tests can be used to assess the impact loads that aircraft structures and .The Charpy impact test, also known as the Charpy V-notch test, is a high strain-rate test that involves striking a standard notched specimen with a controlled weight pendulum swung from a set height. The impact test helps measure the .

The Charpy test is a standardized procedure designed to measure the energy absorbed by a material during a sudden impact load. This evaluation method assesses the material's .The Charpy V Notch (CVN) test is a basic method for defining toughness and, in this process, toughness is defined in “joules or ft lbs” at the “temperature of test”. There are other, more complex methods but the CVN test is cheap, is a good .ABSTRACT: This paper provides a broad overview of the progress in procedural improvements for Charpy impact testing. It includes a short summary of early developments, a discussion of .

charpy impact testing procedure

For a comprehensive solution to test impact toughness in metals, our Charpy Impact Tester for Metals is designed to meet ASTM E23 standards, ensuring high-quality and reliable results. If your focus is on plastics or polymers, the Charpy Izod Pendulum Impact Tester for Plastics is perfect for assessing the toughness of non-metal materials. The Charpy impact test (Charpy V-notch test) is used to measure the toughness of materials under impact load at different temperatures! Test setup and test procedure. In the Charpy impact test, a notched specimen is .The impact strength of structural constructions for instance bridges tends to be accurate when a Seamless Tube Charpy V Impact tested pipes are used to build them. There are several specifications that could be used to create .

Rules for using materials below its MDMT without impact testing. The use of a material at a design minimum temperature colder than −29°C (−20°F) is established by para. 323.2.2 and other impact test requirements. For carbon steels with a letter designation in the Minimum Temperature column, the curve in Figure 323.2.2A of ASME B 31.3 . History of the Charpy impact test. The history of Charpy V-notch impact testing dates back to the early 1900s when French engineer Georges Charpy developed a standardized method for testing the impact toughness of materials, particularly metals. His work led to the creation of the Charpy impact test, which involved striking a standardized specimen with a .

mercury outboard compression test 2001 saltwater

Charpy impact test principle: Charpy impact test is to place the pipe fittings’ sample with the specified shape,size and notch type on the sample holder of the impact tester so that it is in the state of simply supported beam.Then one-time strike the pipe fittings’ sample with a pendulum of a prescribed height,which is essentially the energy conversion process that .The charpy impact test of steel pipes has a wide range of applications. Aerospace Industry: Charpy impact tests can be used to assess the impact loads that aircraft structures and components may encounter during flight.This has an important impact on the safety and durability of the aircraft. Materials science research: In the development process of high-strength steels .Impact Test Impact tests are made on at least one sample machined from the pipe wall dur-ing each operating hour to ensure the desired toughness in the finished pipe. Notched Charpy impact tests are per-formed in accordance with ASTM E23, except that specimen size is 0.500" by full thickness of the pipe wall. The corrected acceptance value for .This page introduces the Charpy impact test principle and methods; as well as evaluation methods, test piece standards, differences from the Izod impact strength test, and methods for measurement of the fracture surface. The 3D Solutions Library operated by KEYENCE introduces examples of shape measurement problems and the latest solutions for various industries, .

The Charpy V-notch-CVN impact test, also known as the Charpy V-notch test, is a standardized high strain-rate test which determines the amount of energy absorbed by a material during fracture. . HYSP Steel Pipe supply you ERW Steel Tubing 12inch ASTM A53 B SCH40 or API 5L ERW steel pipes for your gas and oil line pipe or water pipes . Discover the EN ISO 148-1 standard for the Charpy test, which measures the impact resistance of metals through the energy absorbed. +39 02 9098 1113 [email protected]. Home; Company; . In the field of metal pipe inspection, the Charpy test is essential to verify the resistance of materials to fractures caused by impacts during their . For example, carbon steel products such as A105 flanges, A234 WPB fittings, and A106 grade B carbon steel pipe with a wall thickness of ½ in. and less, when used at a minimum design metal temperature (MDMT) of -20 degrees F, have been exempt from impact testing because of their traditional role in such applications.

According to current Charpy test standards (ASTM E23-12c and ISO 148-1:2009), absorbed energy (KV) results from partially fractured test specimens can be averaged with the results from fully fractured specimens. However, most researchers agree that if a specimen does not fully fracture at the end of a Charpy test, a significant

In an impact test, the test piece is shaped into a rectangle, with the “notch” being made in the middle of the length of the rectangle on one side. The purpose of the impact test is to measure the force needed to break the test piece at the notch when hit with a pendulum against the long side of the test piece in the middle of the notch..the right impact test equipment for standard-compliant testing! Impact testers help determine the failure behavior of materials or components under rapid loads and changing temperatures. Because many materials used for a number of . Filler metals undergo rigorous testing to ensure they provide proper impact toughness to endure rapid loading, extreme temperatures or other stressors. The C. The Charpy impact test, also commonly referred to as the Charpy V-notch test by material scientists, serves as a standardized high-strain rate examination to quantify the energy absorbed by a material upon fracture. The .

Charpy impact testing was initially adopted for testing metals and then used in many early impact studies on FRP composites. The energy absorption and dissipation during the impact event as well as the failure mode can be tested. The specimen is usually in the form of a thick beam with or without a notch and is supported freely at two ends, as shown in Fig. 3 (a). This paper presents the results of the Charpy V-Notch (CVN) impact test for the ST, TL, TS, LS, LT, 45°, and SL directions in API 5L X52 pipelines with electric-resistance-welded (ERW) and .

pipes were manufactured to AWWA C200 standards using the spiral forming method. Testing conducted on all of the samples were Charpy impact, yield strength, ultimate tensile strength, elongation, hardness, and grain structure. Pipe Manufacturing Process The most commonly used pipe manufacturing method for steel water pipe is spiralV-notch Charpy impact test has been widely used to qualify toughness of steels and welds (e.g., [5, 6]). In this work, instrumented Charpy tests of pre-charged steel specimens were conducted at ambient temperature using a pendulum machine with a capacity of 750 J. Two to three repetitive specimens were tested for each pre-charging condition.

The Charpy impact test (CVN) is still the most widely used test for evaluating the absorbed energy and transition temperature of line-pipe steels because of its simple testing method and fewer constraints on specimens [4,5,6].Tested pipes are widely recognized to have sufficient strength and toughness to be applied to very low-temperature pipelines [].

Significance and Use 5.1 Brown and Lu4,5 show the Charpy impact energy is related to the ultimate critical temperature of the rapid crack propagation [RCP] behavior as measured by the ISO 13477, S-4 test.6 5.2 The test method may be used to determine the

Scope- This standard specifies the Charpy impact ( V-notch ) method for determining impact strength of the metallic material. 2. Principle - This test consists in breaking by one blow from a swinging pendulum, under conditions defined hereafter, a test piece V-notched in the middle and resting on two supports.Impact testing, including charpy impact testing, can determine material toughness and yield strength. Impact testing at Laboratory Testing Inc. is performed . Charpy Impact Testing Results. Average values for Charpy impact tests results are listed in Table 3. The variations of CVN energy with respect to the test temperatures for BM, SW, and GW metals also are shown in Fig. 14. In this figure, the tested specimens show an upper-shelf energy region, lower-shelf energy region, and ductile–brittle .

charpy impact testing methods

Charpy Impact test base metal and production weld samples at –320F. Unless the ratio of allowable to design stress is less than 0.35, in which case Impact Test (Toughness Test) is not required. The Owner must review and accept the validity of this approach for the application.

merits and demerits of unconfined compression test

metacarpal compression test

web3 de nov. de 2023 · Acompanhe o sorteio da Lotofácil 2945 e confira o resultado do dia 03 de novembro de 2023, sexta-feira, com o prêmio de hoje estimado em R$ 1.700.000,00 .

charpy impact test on pipe|charpy impact test formula